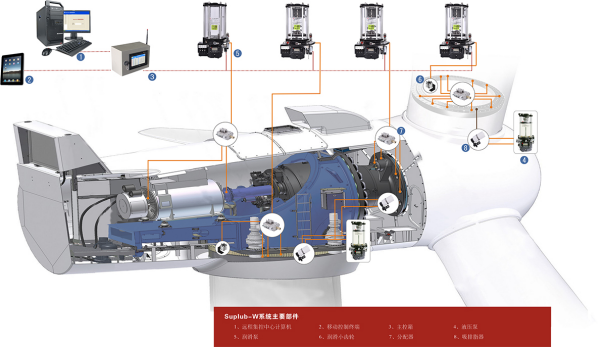

- Intelligent centralized lubrication Suplub-w system

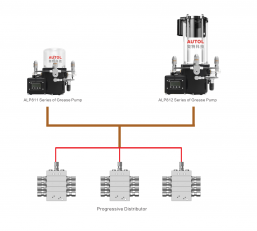

Suplub-W wind power centralized lubrication system provides two solutions including integrated single-line centralized lubrication system and progressive centralized lubrication system.

- It may ensure turbine operation free of trouble and reduced unexpected shutdown

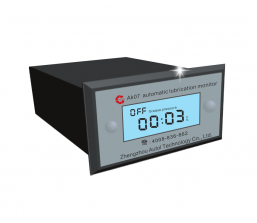

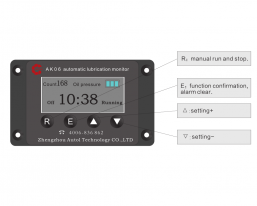

Autol wind power centralized lubrication system is designed with smart central lubrication. Via system transmission port, it may realize remote lubrication on-line control and monitoring and perform on-line monitoring of system operating status while remotely modify the operating parameters of the lubrication system to ensure better bearing lubrication. Autol's waste grease collection system for wind farm may maximize bearing reliability and stability and operator's working safety in wheel hub. Smarter and more controllable bearing lubrication environment reduces damage to bearing and lose in output of power generation due to bad grease discharging, increases its service life, and reduces shutdown frequency and duration

- It simplifies services and prolongs system maintenance interval

In order to ensure bearing good lubrication of wind farm, the waste grease in the internal bearing chamber must be removed. In a wind farm in Inner Mongolia in China, before the Autol's patent product Suplub-W automatic waste grease collection system was installed, the grease seal of pitch bearings of this wind power generator was heavily spilled. After this system has been in stable use for almost 9 months, the automatic waste grease collection system sucked waste grease from the bearing approximately equaled to the new grease filled into the bearing by the centralized lubrication system. After replacement, no grease spilled from the grease seal, avoiding pollution and increasing bearing service life. Autol waste grease collection system of wind farm is used with centralized lubrication system, causing better result of operation, cyclic operation at a fixed interval for several minutes each time. Correct centralized lubrication system may simplify services, prolong interval of system maintenance and protect equipment under various climate conditions.

- The service life of the lubrication parts may be increased by 60% and above

For the conventional manually operated lubrication, the grease filled is uneasily controlled and leakage from grease nipple, dust, etc. will be entrapped into the friction pair causing worse wear. For the centralized lubrication system, the grease lines are fully enclosed to ensure clean lubrication. The service life of the lubrication parts may be increased by 60% and above due to grease supply at fixed time, fixed amount and high frequency.

中文

中文 English

English Español

Español Français

Français