- 1.WHAT IS CENTRALIZED LUBRICATION SYSTEMS?

Centralized lubrication system (CLS) sometimes referred to automatic lubrication system (ALS),is a system that delivers controlled amounts of lubricant (either grease or oil) to multiple locations (lubrication points) on a machine while the machine is operating.For the purpose of reduction in friction resistance and surface friction, and lower temperature of friction surface.

- 2.HOW MANY TYPES ABOUT OUR CENTRALIZED LUBRICATION SYSTEMS?

Single-row Single-line Centralized Lubrication System(CLS);

Progressive Centralized Lubrication System (CLS);

Multi-point Centralized Lubrication System (CLS).

Single line lubrication system

Describe:

Singl line automatic lubrication system consists of plunger lubrication pump, single-line distributor group, monitor, oil pressure sensor, main oil pipeline, oil distribution pipeline and electrical accessories.

auto lubrication system is mainly used in commercial vehicles, automated production lines and other equipment.

Dual line lubrication system

Describe:

There are a variety of connection methods for the two-line centralized lubrication system according to actual needs, and two-line distributors can be connected in series, parallel and series-parallel connection.An oil pressure sensor is provided at the end of the dual line distributor to detect the operating status of the two-line lubrication system.

Intelligent central lubrication system

Describe:

Intelligent auto lubrication system can realize grease supply point by point: it can realize regular, quantitative and fixed point grease supply; Point by point monitoring function: remotely monitor the operation of the system and grasp the operation status of the equipment in time.

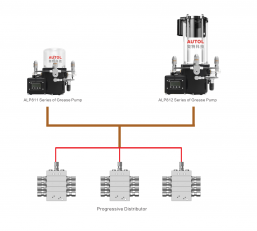

Progressive auto lubrication system

Describe:

The progressive centralized lubrication system is connected to distributors at all levels through a lubrication pump in order to supply grease alternately to each lubrication point to lubricate the friction pair. A plunger detector is set on the main distributor to control the working status of the entire system. The auto grease system can also install a pressure sensor between the lubrication pump and the main distributor to provide early warning of failure.

Automatic greasing system

Describe:

Singl line automatic lubrication system consists of plunger lubrication pump, single-line distributor group, monitor, oil pressure sensor, main oil pipeline, oil distribution pipeline and electrical accessories.The oil injection volume of each lubrication point can be set separately according to the requirements. If one point fails, it will not affect the normal operation of other lubrication points.

- 3.HOW DOES CENTRALIZED LUBRICATION SYSTEMS WORK?

The system controller and injectors are preset to deliver a specific amount of lubricant at a specific interval. To deliver the lubricant, the lubricant pump is activated by the controller, via an air solenoid. This builds pressure in the lines, causing the grease to flow out of the injectors. A pressure switch is incorporated in the system to deactivate the pump once the lubricant injection is complete. In the last step of this process, the system directs any lubricant remaining in the lines back into the reservoir by venting.

- 4.APPLICATION

Centralized systems can be designed to fit almost any application,like Commercial Vehicle / Wind Power / Construction Machinery / Mine / Port / Metallurgy etc.

- 5.WHY CHOOSE US?

RELIABLE QUALITY;

FACTORY DIRECT SALES;

PRICE ECONOMY;

WARRANTY PROVIDE;

ENOUGH STOCK;

SHIPMENT ON TIME.

中文

中文 English

English Español

Español Français

Français