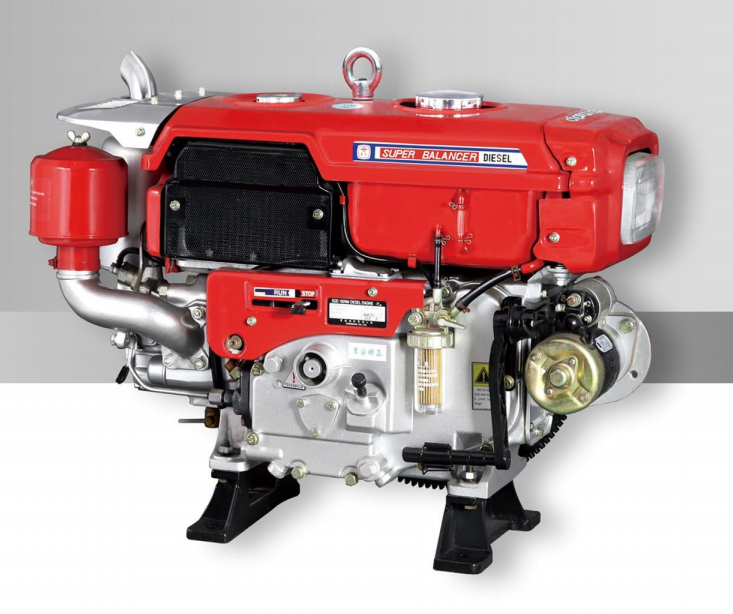

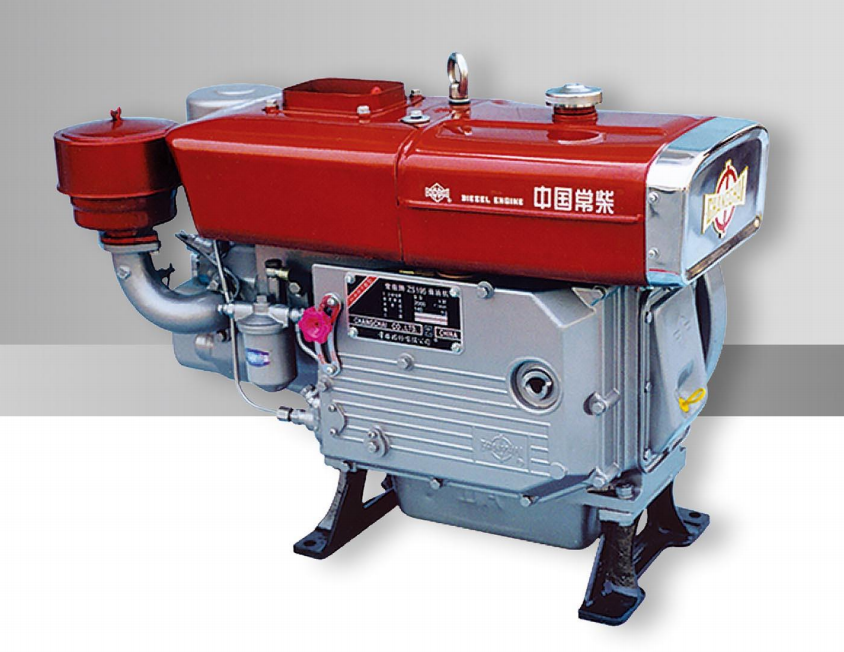

A gasoline engine is a type of internal combustion engine that generates power by burning a volatile liquid fuel. It consists of an engine block, cylinders, pistons, spark plugs, and a crankshaft.

The gas engine can be divided into several types according to fuel management, ignition, piston-and-cylinder or rotor arrangement, strokes per cycle, cooling system, and valve type and location.

- What are the components of the engine?

An engine consists of several different systems that work together to turn fuel into energy. This is done through a series of actions, including combustion, intake, compression, and power.

Combustion occurs inside the engine's cylinders, where air and fuel are mixed and combusted by an electric spark. The resulting heat and pressure causes the pistons to move up and down inside the cylinder.

During this process, the valves open at the proper time to let in the air and fuel, and close at the appropriate time to allow exhaust. The pushrods and lifters control the movement of these valves.

A crankshaft converts the up and down motion of the pistons into rotational motion that allows the engine to move. It's also connected to a camshaft, which controls the timing of the intake and outtake valves. The camshaft and crankshaft are linked by a timing belt that ensures that the valves open and close at the right times for optimal engine performance.

- Multi-cylinder engine Function

Multi-cylinder engines use multiple cylinders and a corresponding number of crankshaft revolutions. This provides higher power output than would be possible with a single cylinder engine of the same displacement.

When a multi-cylinder engine is being used, the air-fuel charge in each cylinder is ignited with the spark plug in turn. The sequence of ignition is usually 1-3-4-2-4, where cylinder 1 fires its power stroke first and then cylinder 2 after.

Another benefit to a multi-cylinder engine is the increased starting torque. Since the pistons have to travel up and down to start each cylinder, they must move at high speeds, which causes vibrations that can be difficult to control with crank shaft counterweights.

To reduce these vibrations and provide more consistent power, a multi-cylinder engine may be provided with a system for deactivating certain cylinders in a firing order. This is known as variable displacement or cylinder deactivation, and it can be found in many automobile engines.

- Gasoline engine Application

Gasoline engines power cars, trucks, and many other machines. They are the most popular way of moving large quantities of people and goods.

In a gasoline engine, fuel and air are ignited to create a mixture of fuels that is then compressed and ignited again. This process is based on the ideal gas law, which states that the pressure in a closed system increases as the temperature of the gases rises.

A gas engine uses a piston to compress the air-fuel mixture, then a spark plug to ignite it. The resulting combustion expands the gases and forces the piston back down the cylinder, doing work.

To help prevent the fuel and air mixture from leaking out of the combustion chamber, the piston is covered by piston rings, springy alloy circles (with a small gap for installation and thermal expansion) that ride in grooves in the piston crown. These rings also prevent most of the byproducts of combustion from leaking past them into the crankcase, diluting the oil.

A gasoline engine is an internal combustion engine that runs on a fuel mixture of petrol (gasoline) and air. It is the most common form of internal combustion engine, and it is used to power all sorts of vehicles from cars to boats.

The engine has 4 basic strokes: intake, compression, power and exhaust. The piston moves up and down in the cylinder to complete these functions, creating a vacuum that draws the fuel-air mixture into the cylinder (intake), compressing it and then igniting it (compression) and expelling the burned byproducts (exhaust).

The most important feature of a gasoline engine is that it burns a volatile liquid fuel with ignition initiated by an electric spark. It can be built to meet the requirements of practically any conceivable power-plant application. It powers passenger automobiles, small trucks, general aviation aircraft, outboard and inboard marine units, moderate-sized stationary pumping, lighting plants, machine tools and power tools.

中文

中文 English

English Español

Español Français

Français