{{i.title_en}}

Powder Metallurgy Contacts Produced By Sintering Extrusion Process

MOQ: 500 PCS

Note: If you have any questions,please contact us

- The composition and quality of the contact products prepared by the powder metallurgy method are easier to control than other process methods, ensuring the consistency of the performance of the contact products.

- Silver graphite contact products are produced by sintering extrusion process, and its density is up to 99.9%.

- Powder contact materials are widely used, the main uses are:Silver tungsten series, Copper tungsten series, Silver tungsten carbide, silver tungsten carbide graphite series, Silver nickel series, Silver nickel graphite series, Silver graphite series.

- Powder contact materials are mainly used in medium and large capacity relays, contactors, small and medium capacity low voltage circuit breakers, AC and DC switches, power protection switches, leakage protection switches, automotive electrical appliances,

- It can be developed and produced according to the specific technical requirements of customers, with an annual production capacity of 60 tons

Longsun Group Co., Ltd

Since:

1986

Product Description

Features:

1.The composition and quality of the contact products prepared by the powder metallurgy method are easier to control than other process methods, ensuring the consistency of the performance of the contact products.

2.Silver graphite contact products are produced by sintering extrusion process, and its density is up to 99.9%.

3.Powder contact materials are widely used, the main uses are:Silver tungsten series, Copper tungsten series, Silver tungsten carbide, silver tungsten carbide graphite series, Silver nickel series, Silver nickel graphite series, Silver graphite series.

4.Powder contact materials are mainly used in medium and large capacity relays, contactors, small and medium capacity low voltage circuit breakers, AC and DC switches, power protection switches, leakage protection switches, automotive electrical appliances, etc..

5.It can be developed and produced according to the specific technical requirements of customers, with an annual production capacity of 60 tons.

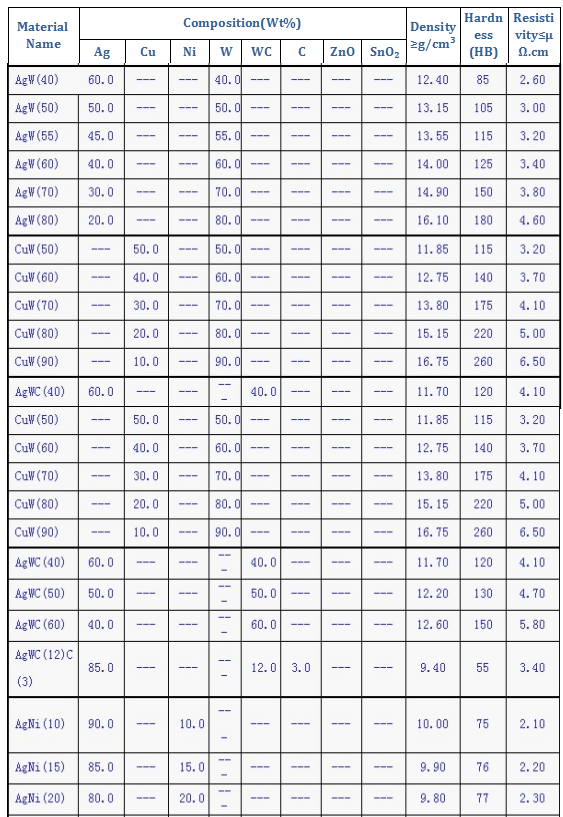

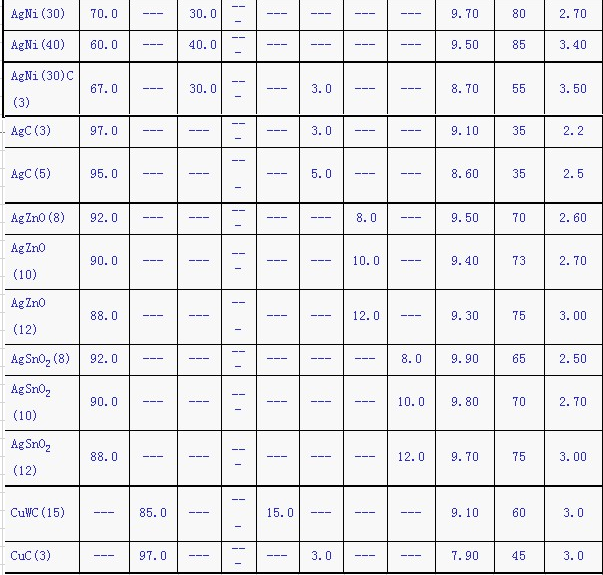

Material composition and physical mechanical properties of powder contact products

中文

中文 English

English Español

Español Français

Français