OMM 12.5CCM MLHM Type Geroler High Speed Small Hydraulic Orbit Motor

MOQ: 0 PCS

Note: If you have any questions,please contact us

- 1.Advanced manufacturing devices for the Gerotor gear set, which provide small volume, high efficiency and long life.

- 2.Shaft seal can bear high pressure of motor of which can be used in parallel or in series.

- 3.Advanced construction design, high power and low weight.

- OMM 12.5ccm

XINGTAI FEIYUE HYDRAULIC PARTS FACTORY

Since:

1985

You May Also Like

Product Description

OMM 12.5CCM MLHM Type Geroler High Speed Small Hydraulic Motor

OMM series motor are small volume, economical type, which is designed with shaft distribution flow, which adapt the Gerotor gear set design and provide compact volume, high power and low weight.

Characteristic features: 1.Advanced manufacturing devices for the Gerotor gear set, which provide small volume, high efficiency and long life. 2.Shaft seal can bear high pressure of motor of which can be used in parallel or in series. 3.Advanced construction design, high power and low weight.

OMM Main Technical Parameters

| Model | OMM-8 | OMM-12.5 | OMM-20 | OMM-32 | OMM-40 | OMM-50 | |

| Geometric displacement(cm²/rev.) | 8.2 | 12.9 | 19.9 | 31.6 | 39.8 | 50.3 | |

| Max.speed(rpm) | cont. | 1950 | 1550 | 1000 | 630 | 500 | 400 |

| int. | 2450 | 1940 | 1250 | 800 | 630 | 500 | |

| Max.torque (N*m) | cont. | 11 | 16 | 25 | 40 | 45 | 46 |

| int. | 15 | 23 | 35 | 57 | 70 | 88 | |

Max.output (kw) | cont. | 1.8 | 2.4 | 2.4 | 2.4 | 2.2 | 1.8 |

| int. | 2.6 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | |

| Max.pressure drop (MPa) | cont. | 10 | 10 | 10 | 10 | 9 | 7 |

| int. | 14 | 14 | 14 | 14 | 14 | 14 | |

Max.flow (L/min) | cont. | 16 | 20 | 20 | 20 | 20 | 20 |

| int. | 20 | 25 | 25 | 25 | 25 | 25 | |

| Max.inlet pressure (MPa) | cont. | 17.5 | |||||

| int. | 22.5 | ||||||

| Net weight (kg) | 1.9 | 2 | 2.1 | 2.2 | 2.3 | 2.4 | |

*Rated speed and rated torque: output value of speed and torque under rated flow and rated pressure; *Continuous pressure: Max.value of operating motor continuously; *Intermittent pressure: Max. value of operating motor in 6 seconds per minute; *Peak pressure: Max.value of operating motor in 0.6 second per minute. | |||||||

1.The maximum working pressure refers to the maximum inlet pressure,while the continuous working pressure refers to the differential working pressure.

2.The motor can not work at the maximum pressure and speed at the same time. 3.Under intermittent working conditions,teh running time shall not exceed 10% per minute.

4.68# anti-wear hydraulic oil with viscosity 37-73 Cst and cleanliness ISO18/13 is recommended.

5.The highest working oil temperature is 80℃。

6.Before the motor works at full load,it should run in under 40% of the maximum working pressure for 1 hour.

7.The maximum back pressure of the motor is allowed to be 10MPa,but it is recommended not to exceed 5 MPa.

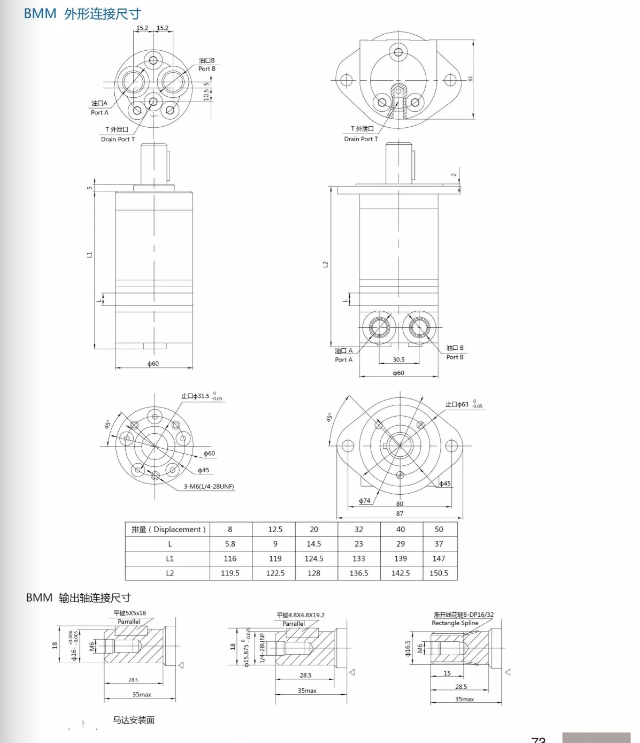

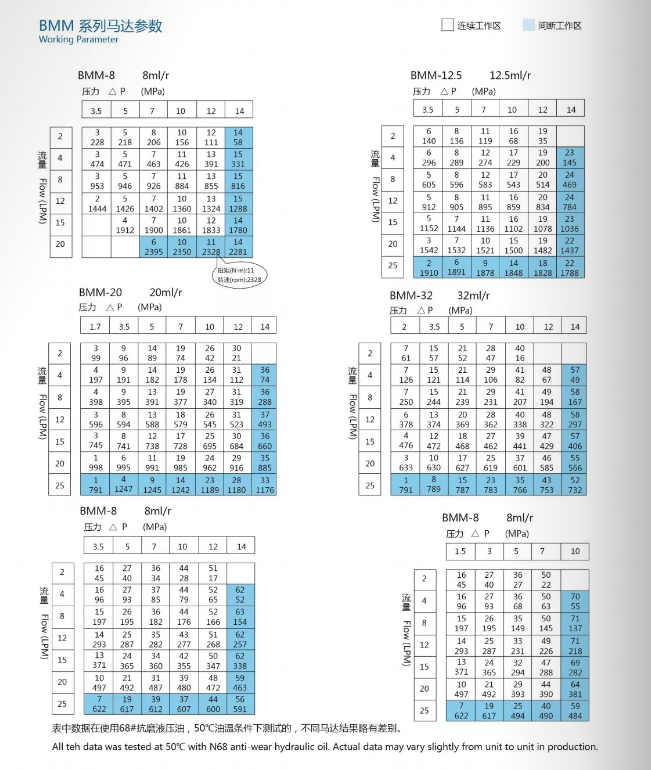

Product list :fei yue catalogue 2021

Hydraulic motor spare part and production line:

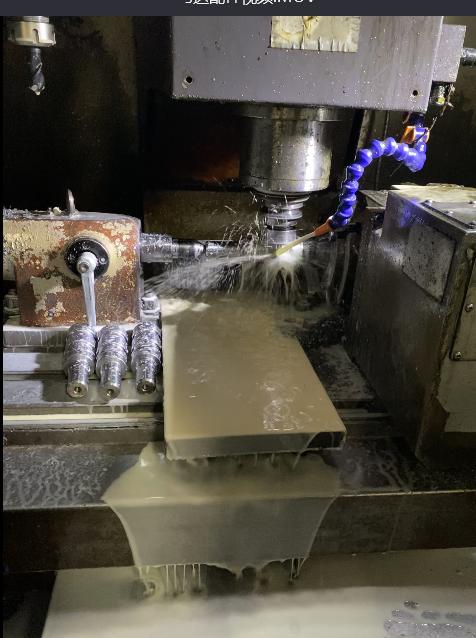

1.Hydraulic motor body BEFORE processing.

2.Picture of shell processing equipment.

3.Hydraulic motor body AFTER processing.

1. Hydraulic motor inside contact Shaft BEFORE Processing

2. Equipment for processing internal contact shafts

3.Hydraulic motor inside contact shaft AFTER processing.

1.Hydraulic motor drlve shaft BEFORE processing.

2.Hydraulic motor drlve shaft processing machine

3. Hydraulic motor drlve shaft AFTER processing.

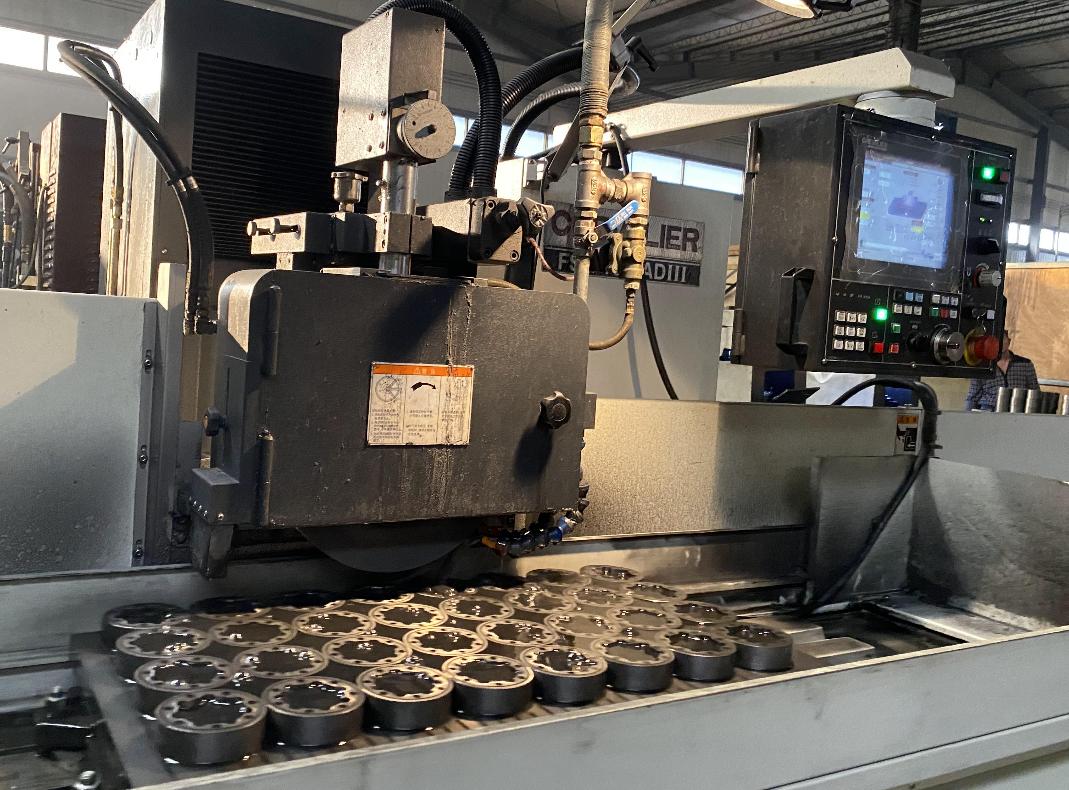

1.Hydraulic motor stator BEFORE processing

2.Hydraulic motor stator processing machine

3.Hydraulic motor stator AFTER processing

Outgoing pictures and product certification

中文

中文 English

English Español

Español Français

Français