{{i.title_en}}

Hydraulic Motor BMR OMR 400CCM for Danfoss 151F-2206

MOQ: 100 PCS

Note: If you have any questions,please contact us

- 1. Compact design, which provide small volume,high power and low weight.

- 2. Credible design,for shaft seal,which can bear high pressure and be used in parallel or in series.

- 3. Direction of shaft rotation and speed can be controlled easily and smoothly.

- 4. Best combination of efficiency and economy in medium load applications

- 5. Advanced manufacturing devices for the Gerotor gear set, high efficiency and long life.

- 400CCM

XINGTAI FEIYUE HYDRAULIC PARTS FACTORY

Since:

1985

Product Description

Replacement for Danfoss OMR series Hydraulic Motor 50/63/80/100/160/200/315/400cc,2-Bolt Mounting Flange ,G1/2 NPT Ports

1.Double needle bearing can bear higher radial force,with more Concentricity that can help smooth running under the high speed condition;

2. High quality oil seal lead to longer service life;

3.Shaft seal can bear high pressure of back and the motot can be used in parallel or in series;

4.Special design in the driver-linker and prolong operating life;

5. Special design for distribution system can meet the requirement of low noise of unit;

6.Integration of efficiency and economy to environment-friendly; Compact volume and easy installation;

Product list :fei yue catalogue 2021

BMP Main Specification

| TYPE | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | BM1 | |

| OMR | OMR | OMR | OMR | OMR | OMR | OMR | OMR | OMR | OMR | ||

| Displacement(ml/r) | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | |

Flow (LPM) | Continuous | 45 | 45 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Intermittent | 50 | 50 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | |

Speed (RPM) | Continuous | 879 | 720 | 740 | 589 | 475 | 370 | 296 | 237 | 189 | 149 |

| Intermittent | 975 | 755 | 827 | 673 | 594 | 463 | 370 | 297 | 236 | 185 | |

Pressure (MPA) | Continuous | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 11 | 11 | 11 | 10 |

| Intermittent | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 16.5 | 14 | 12.5 | 10.5 | |

Torque (N*.m) | Continuous | 81 | 101 | 129 | 161 | 202 | 245 | 286 | 360 | 406 | 435 |

| Intermittent | 108 | 134 | 171 | 213 | 268 | 342 | 390 | 456 | 505 | 533 | |

1. Continuous pressure:Max.value of operating motor continuously. 2.Intermittent pressure:Max.value of operating motor in 6 seconds per minute . 3.Peak pressure:Max.value of operating motor in 0.6 second per minute. 4.The optimum operating situation should be at the 1/3-2/3 of the continuous operating situation. | |||||||||||

Replace DANFOSS No

| 151F-0500 | 151F-0522 | 151F-2206 | 151F-2242 | 151F-2305 | 151F-2327 | 151F-2354 |

| 151F-0501 | 151F-0523 | 151F-2207 | 151F-2243 | 151F-2306 | 151F-2328 | 151F-2355 |

| 151F-0502 | 151F-0524 | 151F-2208 | 151F-2244 | 151F-2307 | 151F-2329 | 151F-2356 |

| 151F-0503 | 151F-0525 | 151F-2209 | 151F-2245 | 151F-2308 | 151F-2330 | 151F-2357 |

| 151F-0504 | 151F-0526 | 151F-2210 | 151F-2246 | 151F-2309 | 151F-2331 | 151F-2358 |

Replace Eaton/Char-Lynn

| 104-1001 | 104-1032 | 104-1066 | 104-1198 | 104-1376 | 104-1421 | 105-1060 |

| 104-1002 | 104-1033 | 104-1067 | 104-1199 | 104-1377 | 104-1422 | 105-1071 |

| 104-1003 | 104-1034 | 104-1068 | 104-1200 | 104-1378 | 104-1423 | 105-1072 |

| 104-1004 | 104-1035 | 104-1087 | 104-1201 | 104-1379 | 105-1001 | 105-1073 |

| 104-1005 | 104-1037 | 104-1088 | 104-1202 | 104-1380 | 105-1002 | 105-1074 |

Replace M+S Hydraulic

| MS 80 | MS 100 | MS 125 | MS 160 | MS 200 | MS 250 | MS 315 | MS 400 | MS 475 |

| MSS 80 | MSS 100 | MSS 125 | MSS 160 | MSS 200 | MSS 250 | MSS 315 | MSS 400 | MSS 475 |

| MLHS 80 | MLHS 100 | MLHS 125 | MLHS 160 | MLHS 200 | MLHS 250 | MLHS 315 | MLHS 400 | MLHS 475 |

| MLHSS 80 | MLHSS 100 | MLHSS 125 | MLHSS 160 | MLHSS 200 | MLHSS 250 | MLHSS 315 | MLHSS 400 | MLHSS 475 |

| MLHSW 80 | MLHSW 100 | MLHSW 125 | MLHSW 160 | MLHSW 200 | MLHSW 250 | MLHSW 315 | MLHSW 400 | MLHSW 475 |

Hydraulic motor spare part and production line:

1.Hydraulic motor body BEFORE processing.

2.Picture of shell processing equipment.

3.Hydraulic motor body AFTER processing.

1. Hydraulic motor inside contact Shaft BEFORE Processing

2. Equipment for processing internal contact shafts

3.Hydraulic motor inside contact shaft AFTER processing.

1.Hydraulic motor drlve shaft BEFORE processing.

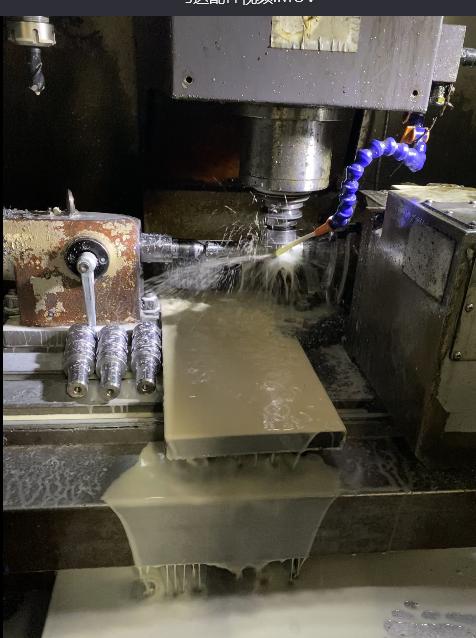

2.Hydraulic motor drlve shaft processing machine

3. Hydraulic motor drlve shaft AFTER processing.

1.Hydraulic motor stator BEFORE processing

2.Hydraulic motor stator processing machine

3.Hydraulic motor stator AFTER processing

Outgoing pictures and product certification

中文

中文 English

English Español

Español Français

Français